Nordson MEDICAL has 50+ years of experience designing, developing, and manufacturing finished medical devices and subassemblies leveraging our deep expertise in component technologies. This vertical integration helps teams reduce costs, mitigate risk, streamline supply chain, and ensure consistent quality.

Prototype to Production Solution

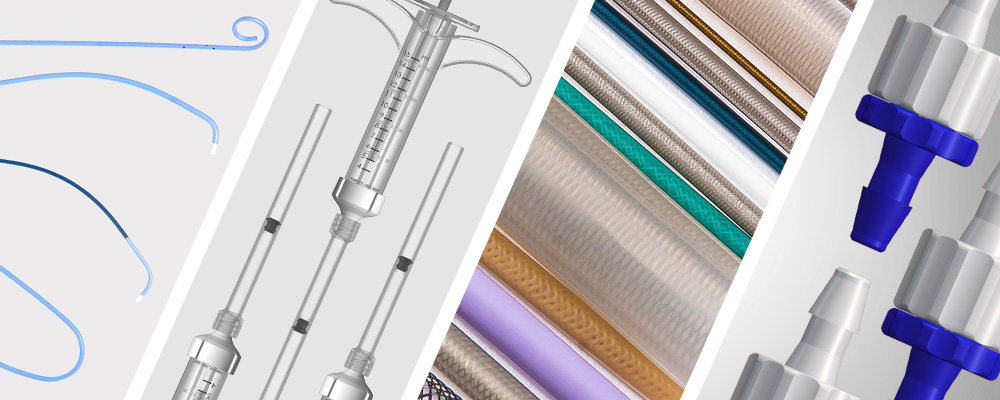

We provide a full range of services to bring to life a broad range of complex medical devices and components, including:

- Catheters & Cannulae

From simple access catheters to complex therapeutic catheters, we provide custom options to meet your needs

- Shafts & Sheaths

We engineer shafts that meet your clinical and technical requirements, from braid- or coil-reinforced tubing to complex steerable devices

- Fluid Management Solutions

We provide subassemblies and tubing sets leveraging stock and custom fittings

- Delivery Devices

Whether you're delivering an implant, a drug, a biomaterial, or other therapy, we can work with you on a custom solution

Integrated Device Manufacturing

We can leverage our in-house component and technology expertise to design, develop, and manufacture finished medical devices and subassemblies. Our capabilities include:

- DFM/DFA analysis and redesign

- Process design and development

- Product verification and validation testing

- Robust design transfer process and tools

- Dedicated transfer teams

- Low- to high-volume manufacturing

- Manual, semiautomated, and fully automated finished good assembly

- Inspection and quality assurance

- Packaging and labeling

- Sterilization validation and management

- Robust continuous improvement initiatives

- Global supply chain management system

- Global Quality System

Continuous Improvement

Business excellence is integral to our culture. From the leaders of our facilities to each and every employee, we are dedicated to the principles of Lean: maximizing customer value while minimizing waste. When you partner with us, you can have confidence that we’re always striving to maximize safety, improve quality, optimize processes, and foster innovation, with the ultimate goal of bringing our customers’ innovations to life faster and more efficiently.

Nordson MEDICAL uses Continuous Improvement as a systematic, proactive, and disciplined management process to continually improve the safety, quality, service delivery, and cost of our medical device manufacturing and assembly services. Nordson MEDICAL implements cost reduction projects during the year in the areas of material, labor, and overhead, always focusing on maximizing customer value.

Rigorous Approach

Our enterprise-wide approach to business excellence leverages Lean and Six Sigma methodologies to continuously improve the quality of our medical device manufacturing and assembly services:

- Maximize safety

- Drive quality and predictable processes

- Reduce variation and eliminate defects

- Streamline and standardize processes

- Improve production stability and capabilities

- Eliminate waste

- Reduce costs and inventory

- Optimize service delivery

Lean & Six Sigma Certification Program

Hundreds of our employees are trained and certified in Six Sigma and Lean, with more being trained every year. Lean Enterprise Academy Training develops expertise in continuous improvement techniques including:

- Kaizen events

- Rapid Improvement Events (RIE)

- 5 Principles for Problem Solving

- 3P (Production, Preparation, Process) Design for Manufacturability

- Value Stream Mapping for identifying waste

- DMAIC methodology (define, measure, analyze, improve, control)

- Lean Business Process Improvement

Compliance Through Automation

One of the ways we ensure the highest level of quality and compliance in medical device manufacturing is by implementing proven automated processes and systems, including:

- Electronic quality management system

- Statistical Process Control (SPC) software

- Production and process monitoring system

- Precision, optical, measurement system