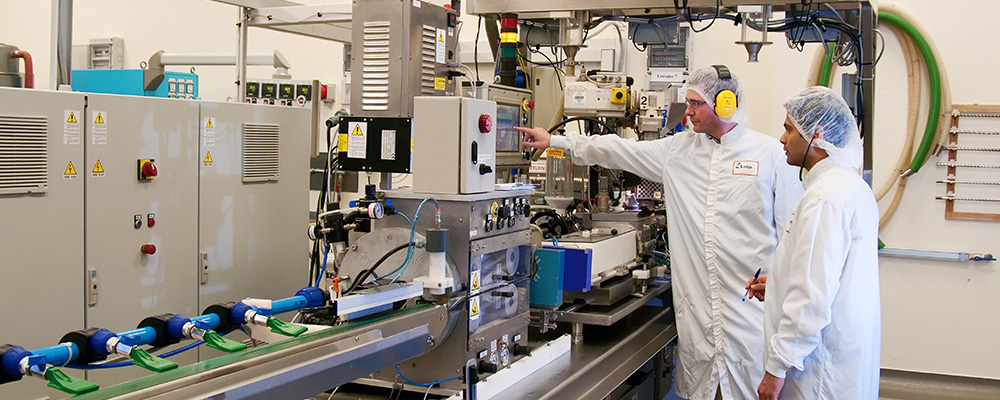

Also referred to as melt fluoropolymers as they are processed with traditional extrusion equipment, our line of fluoropolymer tubing is created through a proprietary compounding/blending process that provides custom color and radiopaque fillers while maintaining strict process control.

From pellet to product, Nordson MEDICAL processes an array of fluoropolymer materials including FEP, PFA, PCTFE, ETFE, PVDF, ECTFE, and EFEP. Nordson MEDICAL is one of the few companies in the world with expertise across all of these raw materials.

What are Fluoropolymers?

Fluoropolymers are chemically similar to polyolefins, with the exception of substituting fluorine for hydrogen. This drastically changes the properties. Fluorine's electronegativity causes the bond between carbon and fluorine to be the strongest bond in organic chemistry. This strong bond lends itself to fluoropolymers, achieving high temperature resistance, lubricity, electrical resistance, dielectric strength, and low reactivity.

All of these properties lend to fluoropolymers being extremely biocompatible, and thus ideal, for medical applications. Their drawback is in long-term-use applications under load, as fluoropolymers are notorious for cold-flow, or material creep.

Fluoropolymer Properties Chart

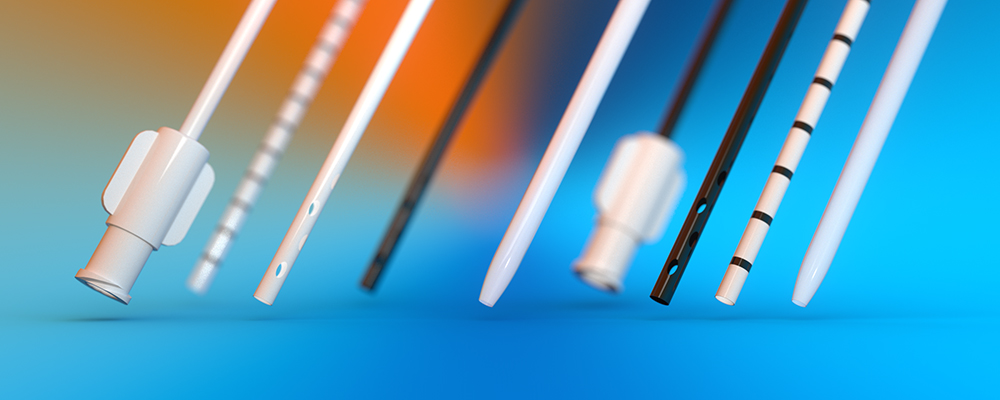

- Fluoropolymer Tubing Options

- Single-lumen tubing

- Multi-lumen/profile extrusions

- Radiopaque tubing

- FEP heat shrink tubing

- Device Components

- Filled fluoropolymers

- Custom colors

- Radiopaque fill/stripe

- Etched liners

- Tubing for packaging

- Value-Added Features

- OD etching

- Bondability to outer jacket

- Dip etching

- Atraumatic taper and radius tips

- Flanging and flaring

- Notching and drilling

- Welding

- Integration of radiopaque tip

- Visibility under x-ray or fluoroscopy imaging

Fluoropolymer Etching

Fluoropolymers are known for their combination of superior properties, whether chemical, electrical, or physical. Chances are that when you choose to use a fluoropolymer, it will have to be bonded with another part, whether metal, plastic, ceramic or composite, in order to perform its intended function. This can be a problem, since fluoropolymers are notorious for their lack of bondability. This lack of bondability is caused by the very stable, covalent carbon-fluorine bonds that make up your fluoropolymer. These bonds are so stable that the polymer has difficulty bonding to anything else, even temporarily. To improve bondability, one must remove some of these carbon-fluorine bonds. This process is called fluoropolymer etching, and is a solution that Nordson MEDICAL offers to combat the bondability problem.

Etching is a chemical process that removes the fluorine atoms from the surface layer of the fluoropolymer. This surface layer is so thin; it is most conveniently measured in Angstroms. Once the fluorine atoms are removed, the carbon atoms left behind in the etched polymer quickly form temporary bonds with atoms from the air, such as oxygen, nitrogen, and sometimes even hydrogen. Since these bonds are much weaker, the carbon atoms are still reactive, reducing the surface lubricity and allowing for a more bondable product. Because of the loss of carbon-fluorine bonds, once the surface of your fluoropolymer is etched, the properties of the etched area are changed. One will no longer have the lubricous and low energy surface that is expected from a fluoropolymer. Instead, one will have a wettable, bondable, frictional surface upon which to glue, mold, or print onto your product.

While there are a variety of methods available for fluoropolymer etching, Nordson MEDICAL exclusively uses a solution of Sodium Naphthalene for our in house etching processes. We offer alternate etching chemistries through subcontracts currently in place with outside etching companies.

Etching will only affect the chemistry of the surface with which it comes in contact. The properties of your fluoropolymer are kept intact not only underneath the etched surface, but on the entire remaining unetched surface as well, meaning that the etched product's bulk properties are unaffected by this process.

The results of the etching are not permanent, however. If left unused for long periods of time or stored incorrectly, the etched part regains its initial low bondability.

Nordson MEDICAL offers a variety of etching configurations:

- In-line surface (OD) etching during extrusion

- Dip-Etching, which offers more control such that only specific surface areas are etched

- Inside (ID) tube etching

- Aggressive etching that Nordson MEDICAL subcontracts for alternate etch chemistries (please contact our engineering staff for additional information)

At Nordson MEDICAL, all of our fluoropolymer products are custom manufactured to meet our customers' needs. We can assist whether you have a current design or require our engineering support to design an etching solution for your application.