What is a Check Valve?

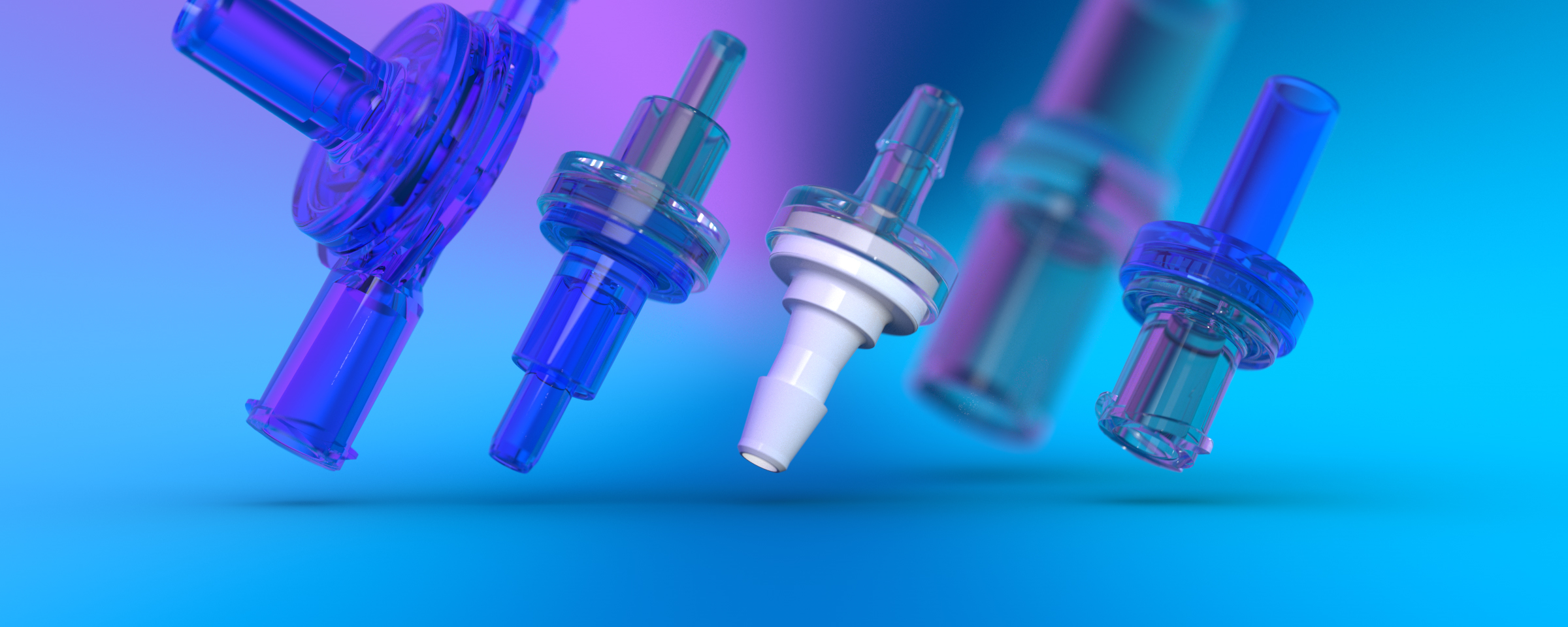

A check valve controls the flow direction of fluids and are available in various configurations depending on the application. Single-configuration check valves are designed to prevent back flow in only one direction. Double-configuration check valves control flow bi-directionally by diverting fluid to multiple outlets consecutively. Single-configuration check valves are normally closed - meaning they require positive pressure differential to allow flow - with various termination options including luers, bond sockets, bond posts, and barbed designs. There are also several opening pressure ratings from precision near zero opening pressure options to the anti-siphon valves which have higher opening pressures to prevent gravity induced flow. Medical grade check valves are made with USP Class VI materials deemed safe for use with the human body. Medical grade check valves reduce the risk of contamination, allow seamless priming, and offer higher flow rates. They are ideal for medical device designers focused on infusion, drainage and irrigation applications.

Single-Configuration Check Valves

Single-Configuration Check Valves, or SCV Series products, are available in anti-siphon, one-way, and barbed configurations in a variety of materials and terminations. The one-way configurations feature male and female locking luers, bond sockets, and bond posts in multiple combinations and sizes. The barbed check valves feature 3/32” (2.4 mm) and 1/8” (3.2 mm) single barb ends in barb to barb straight through, reducing, and barb to male/female luer configurations. Single configuration check valves reduce the risk of contamination and feature more precise, lower opening pressures and higher flow rates. They are ideal for medical device designers focused on infusion, drainage and irrigation applications.

All check valves include DEHP- and latex-free silicone diaphragms and feature a low priming volume, ease of removing air bubbles during priming and operate in any spatial orientation. All materials of construction satisfy USP Class VI and ISO 1099 criteria.

Anti-Siphon Check Valves

Anti-Siphon Check Valves

Nordson MEDICAL Anti-Siphon Check Valves are not only designed to control directional flow and prevent backflow, but also have higher opening pressures to prevent inadvertent fluid flow caused by siphoning when tying into a higher flowing line. They are made from medical-grade quality materials and engineered to operate in any spatial orientation with improved air vent functionality for health care applications such as enteral feeding. Because of these quality materials and design, our anti-siphon check valves meet USP Class VI and ISO 10993 criteria. Our Nordson MEDICAL anti-siphon check valves are the quality choice of health care professionals worldwide.

Visit Online Store

- Designed to prevent backflow

- Materials meet USP Class VI and ISO 10993 criteria

- Air entrapment readily alleviated during priming

- Operate in any spatial orientation

- Normally closed valve for optimum flow control

- Lowest cracking pressure on the market

- Prevents unwanted free flow under gravity

- Improves air vent functionality for applications such as enteral feeding

Materials

Housing

- Methylmethacrylate acrylonitrile butadiene styrene (MABS)

- Styrene acrylonitrile (SAN)

- Polycarbonate

Diaphragm

- Silicone

- Phthalate- and latex-free material

Sterilization

- Gamma radiation stable, EtO compatible

Cracking Pressure

- 1.450 psig - 4.351 psig (100 mb – 300 mb)

Maximum Back Pressure

- 73.000 psig – 304.500 psig (5 bar – 21 bar)

Flow Rate

High-Flow Check Valves

High-Flow Check Valves

Our High-Flow Check Valves are specifically designed with quality medical grade, USP Class VI and ISO 10993 certified materials for the purposes of flushing and irrigating a body cavity. Engineered to increase flow with a less restrictive path, these high-flow check valves provide a more responsive flow and ability to remove air bubbles during priming.

Visit Online Store

- Designed for flushing and irrigation applications

- Materials meet USP Class VI and ISO 10993 criteria

- Easy to remove air bubbles during priming

Materials

Housing

- Methylmethacrylate acrylonitrile butadiene styrene (MABS)

Diaphragm

- Silicone (Phthalate- and latex-free material)

Fits Tubing OD

Sterilization

- Gamma radiation stable, EtO compatible

Cracking Pressure

Max. Back Pressure

Flow Rate

- With water at a pressure of 100 mb; ≥ 1000 ml/min

- With water at a pressure of 1 bar; ≥ 3000 ml/min

One-Way Check Valves

One-Way Check Valves

These One-way Check Valves are not only designed with medical grade materials and engineered to prevent back flow with its closed-valve resting state, these unidirectional valves are designed to operate in any spatial orientation and have the lowest cracking pressure on the market. With its improved air vent functionality for enteral feeding applications and ability to operate in any spatial orientation, our one-way check valves are ideal in any medical application where eliminating backflow is essential.

Visit Online Store

- Designed to prevent backflow

- Materials meet USP Class VI and ISO 10993 criteria

- Air entrapment readily alleviated during priming

- Operate in any spatial orientation

- Normally closed valve for optimum flow control

- Lowest cracking pressure on the market

- Controlled directional flow helps prevent backflow

- Prevents unwanted free flow under gravity

- Improves air vent functionality for applications such as enteral feeding

Materials

Housing

- Methylmethacrylate acrylonitrile butadiene styrene (MABS)

- Styrene acrylonitrile (SAN)

- Polycarbonate

Diaphragm

- Silicone (Phthalate- and latex-free material)

Sterilization

- Gamma radiation stable, EtO compatible

Cracking Pressure

Max. Back Pressure

- 73.000 psig – 116.030 psig (5 bar – 8 bar)

Flow Rate

Barbed Check Valves

Barbed Check Valves

Barbed Check Valves feature 3/32" (2.4 mm) and 1/8" (3.2 mm) single barb ends in barb to barb straight through, reducing, and barb to male/female luer configurations. Barbed check valves reduce the risk of contamination and feature more precise, lower crack pressures and higher flow rates. They are ideal for medical device designers focused on infusion, drainage and irrigation applications.

Visit Online Store

- Ideal for infusion, drainage, and irrigation applications

- Reduces risk of contamination

- Features lower crack pressures and higher flow rates

- Materials meet USP Class VI and ISO 10993 criteria

- Air entrapment readily alleviated during priming

- Operate in any spatial orientation

Materials

Housing

- Methylmethacrylate acrylonitrile butadiene styrene (MABS)

- Styrene acrylonitrile (SAN)

- Polycarbonate

Diaphragm

- Silicone (Phthalate- and latex-free material)

Single Barb Ends

- 3/32" (2.4 mm)

- 1/8" (3.2 mm)

Configurations

- Barb to barb straight through

- Reducing

- Barb to male/female luer

Sterilization

- Gamma radiation stable, EtO compatible

Cracking Pressure

Max. Back Pressure

Flow Rate

Double-Configuration Check Valves

Nordson MEDICAL's unique Double-Configuration Check Valves or DCV Series bi-directional double check valve is designed to transfer clean fluid from a supply vessel to a use site. The fluid supply vessel is connected to the valve supply port (chimney) using a luer connection or tubing. The fluid is withdrawn from the supply vessel by a syringe or other device connected to the aspiration port. When the syringe is compressed the fluid is then transferred, through the exit port, to the use site without adulterating the fluid. DCV Series bi-directional valves are produced in polycarbonate resin using a silicone diaphragm, with two available inlet ports connecting to the female luer aspiration and male luer discharge ports.

Double-Configuration Check Valves

Double-Configuration Check Valves

Our bi-directional double check valves are made with medical grade, USP Class VI certified materials and features quality engineering design that enables the trasnfer of clean fluids from your supply-side to site without disconnecting your syringe. These double check valves also include two available inlet ports - a female luer aspiration port and a male luer discharge port - adding functionality to performance.

Visit Online Store

- Bi-directional double check valve

- Clean fluid transfer from supply to site

- No need for disconnection to fill syringe

- 2 available inlet ports connecting:

- Female Luer aspiration port

- Male Luer discharge port

- Materials meet USP Class VI criteria

- High flow rate

- Low cracking pressure

Materials

Housing

Diaphragm

- Silicone (Phthalate- and latex-free material

Cracking Pressure

- 2 psi – 5 psi (0.14 bar – 0.34 bar)

Custom-Configuration Check Valves

Nordson MEDICAL is your single-source partner for Custom-Configuration Check Valves. We can work with your team from the original idea through production scale up. From customized connecting geometry to valve performance characteristics, we can tailor our check valves to meet your specific requirements in the most demanding applications.

Call the Nordson MEDICAL customer service team at 1-888-404-5837 today, and discover how partnering with Nordson MEDICAL delivers world-class precision in your most demanding applications.

Custom-Configuration Check Valves

Custom Configuration Check Valves

Choosing a partner like Nordson MEDICAL — who will work closely with you to design and develop a check valve that meets your dimensional and performance requirements and supports your product with world-class manufacturing capabilities and regulatory support — can be paramount to the success of your product.