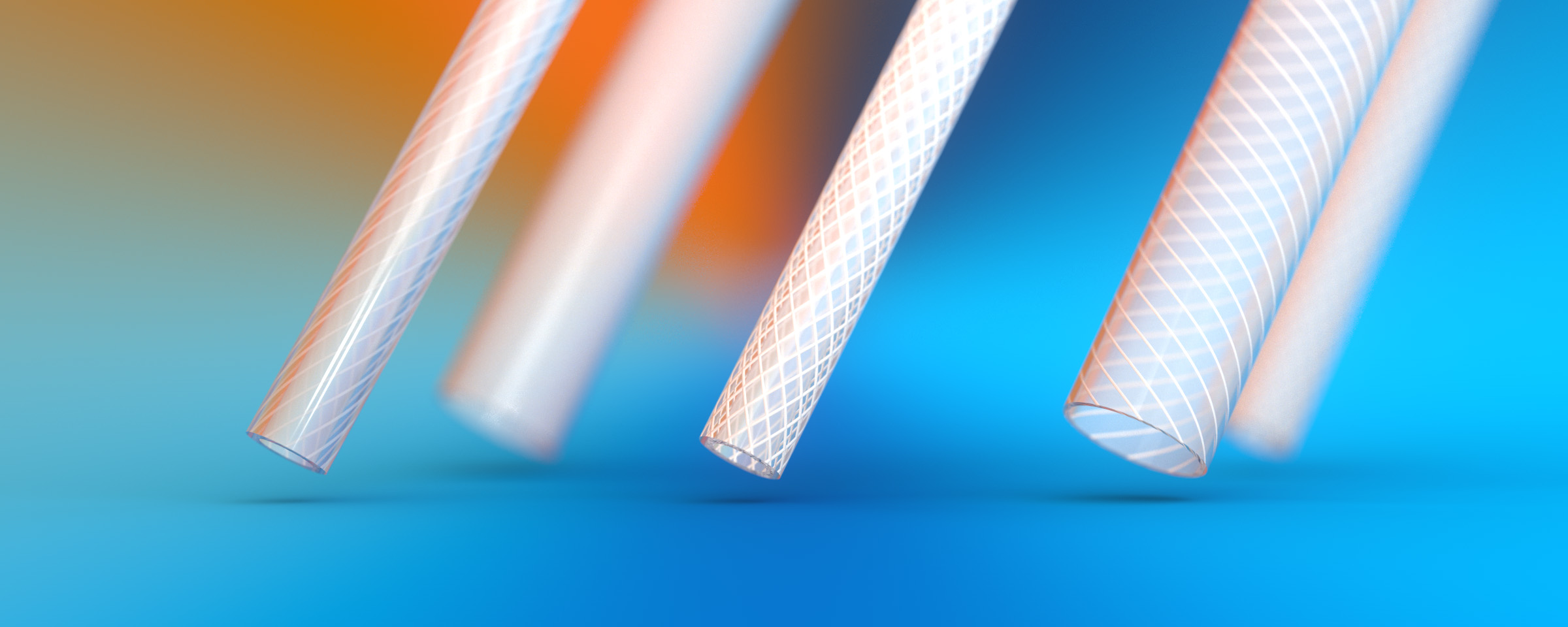

Building on our expertise in medical tubing, Nordson MEDICAL has full capabilities to design and manufacture high-performance reinforced tubing for catheters. Reinforced catheter tubing is ideal for medical device applications that require:

- Strength

- Stiffness

- Flexibility

- Torque

- Kink resistance

- Compression resistance

Experts in Medical Reinforced Tubing

Starting with your clinical requirements, our engineers can work with you to design and manufacture high-performance medical reinforced tubing with the performance characteristics you need. Our capabilities include:

- Braid-reinforced microtubing

- Reel-to-reel braid-reinforced tubing

- High-pressure braided tubing

- Complex coil- and braid-reinforced shafts

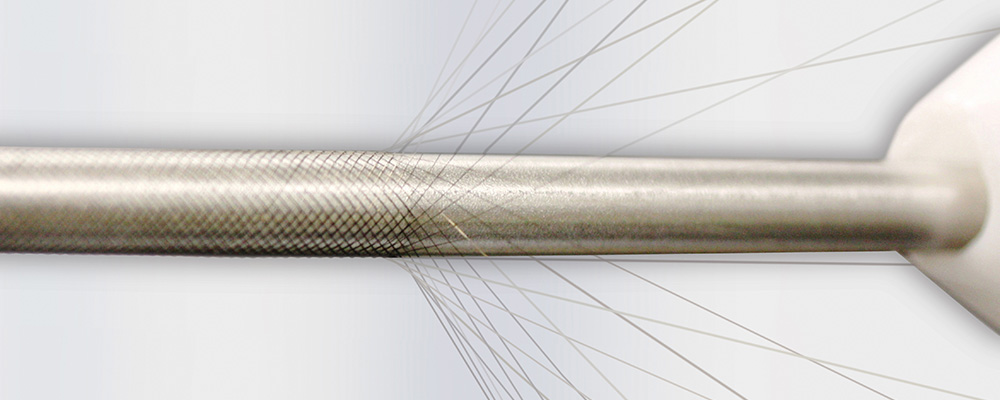

Braid-Reinforced Microtubing

Our braid-reinforced microtubing is fabricated using the film-coat process developed for polyimide tubing and can be braided over PTFE as well.

- 4–5 layers of different materials within a 0.003" wall thickness for each layer

- Metallic and nonmetallic braid reinforcement (8–16 wires)

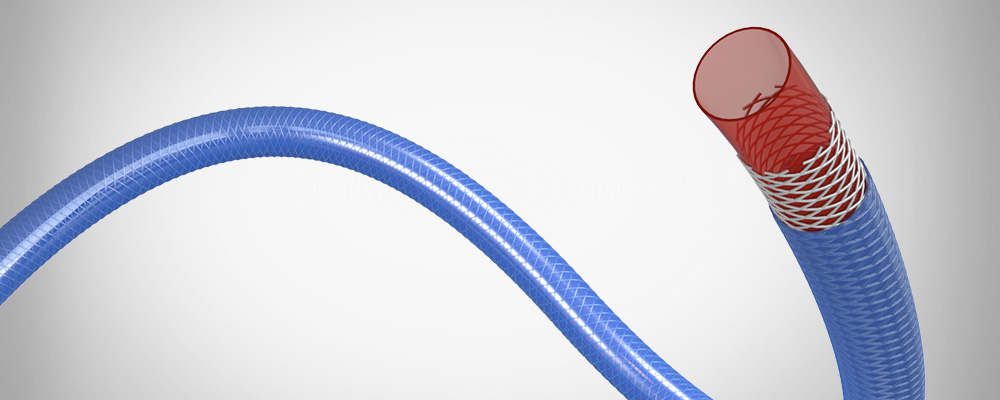

Reel-to-Reel Braid-Reinforced Catheter Tubing

We offer continuous reel-to-reel braiding, which allows us to produce millions of feet of braid-reinforced catheter tubing each year.

- Cost effective

- Consistent and reliable

- Variable pitch in continuous lengths also available

High-Pressure Braided Tubing (HPBT)

High-pressure braid-reinforced tubing is a polyurethane tubing reinforced with polymer monofilament and can be utilized for various applications including high pressure transmission of contrast media into the vascular system. Typical working pressure of 1,200 psi is achievable, and it is EtO sterilizable. It can be manufactured to precise tolerances at high or low volumes. Custom designs are also available.

- Combines high strength and flexibility

- Withstands up to 1,200 psi working pressure

- Custom designs also available

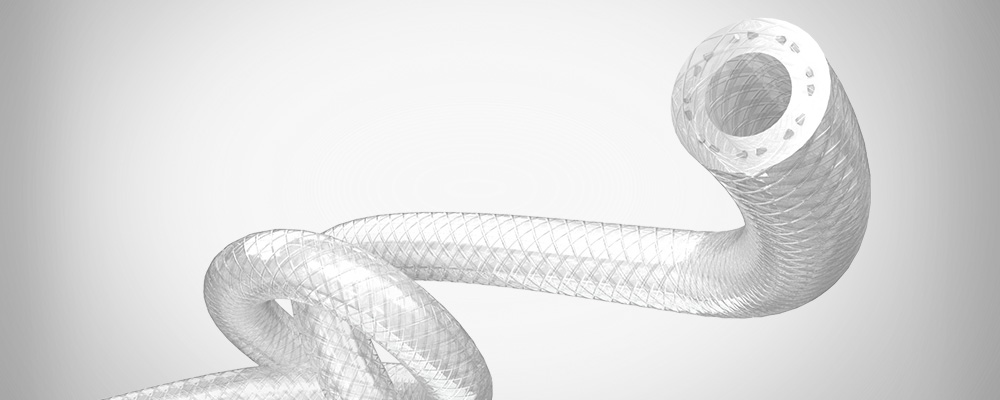

Complex Coil- and Braid-Reinforced Shafts

Our complex coil- and braid-reinforced shafts are designed and manufactured to your specifications. We offer a wide range of dimensions and materials, including polyimide. Contact us to discuss your design intent and we'll work with you to design a device with the performance characteristics you need. Our capabilities include:

- Variable-pitch braid-reinforced shafts

- Coil-reinforced shafts

- 16-, 32-, and 48-carrier braiders

- Fiber/nonmetallic braiding

- Custom tipping

- Custom hole punching & drilling

- Shaping

Vertical Integration

Vertical integration is how we offer customers the most cost-effective, innovative, catheter-based devices on the market. Our Catheter Center of Excellence offers everything you need to build your device, from leading-edge components to design and development support to high-volume manufacturing.