Applications of Engineered Shafts

Medical engineered shafts are designed to achieve a balance of strength, flexibility, torque response, kink resistance, and more. Typical applications of engineered shafts include:

- Delivery Systems: Percutaneous devices are used to deliver a treatment (stent, valve, pharmaceutical, repair, etc.) to a specific anatomical location. Delivery systems can be a single shaft or multiple interacting together to form a system.

- Steerable/Articulating Shafts: These shafts and sheaths are designed with a distal section that can be articulated to navigate the anatomy and precisely deliver a treatment. These devices can be produced with single or multi-plane deflection.

- Guiding Catheters: These reinforced shafts are produced with either braid or coil reinforcement and help guide other interventional devices to a wide-range of anatomy. They typically have an overmolded luer or hub on the proximal end and can be produced with various distal shapes to aid in navigation.

- Introducer Sheaths: These devices can be reinforced or non-reinforced and are utilized to gain access to the vasculature system. They can be produced with valves and flush side-ports to maintain hemostasis during access.

- Micro-Catheters: These catheters are typically in the 1.5-3Fr (0.5-1mm) size range. They are designed to traverse into and through challenging anatomical locations that require small profile/thin walls, high degrees of flexibility, and ovalization resistance while providing pushability to navigate tortuous paths deep into the distal anatomy.

- MRI-Compatible Devices: These delivery systems are constructed with non-metallic components to provide optimal functional performance and safety during use in MRI-based clinical procedures.

- High-Pressure Systems: These delivery systems are designed to handle radial forces experienced during high pressure applications (ex. Cryo treatments).

Technical Expertise + Advanced Capabilities

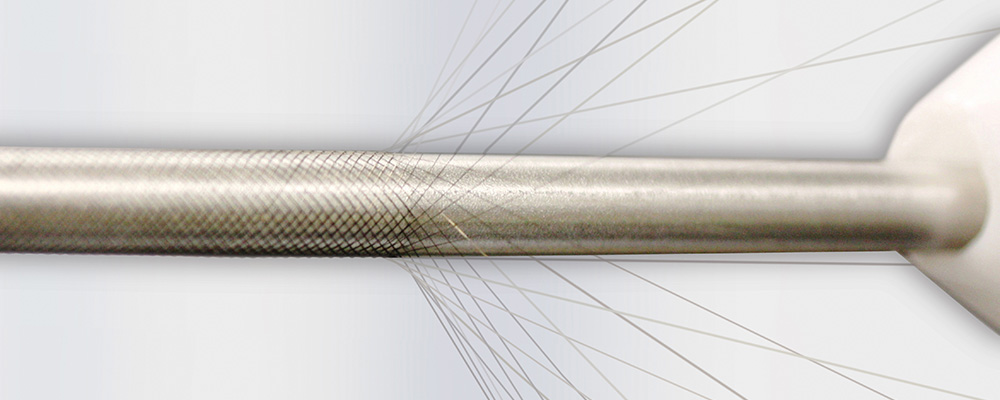

Our experience allows us to quickly understand the performance characteristics and clinical requirements, so we can work with you to design and manufacture medical reinforced shafts that meet your project's needs. Our capabilities include:

- Variable-pitch braid-reinforced shafts

- Coil-reinforced shafts

- 16-, 32-, and 48-carrier braiders

- Fiber/nonmetallic braiding

- Custom tipping

- Custom hole punching & drilling

- Shaping

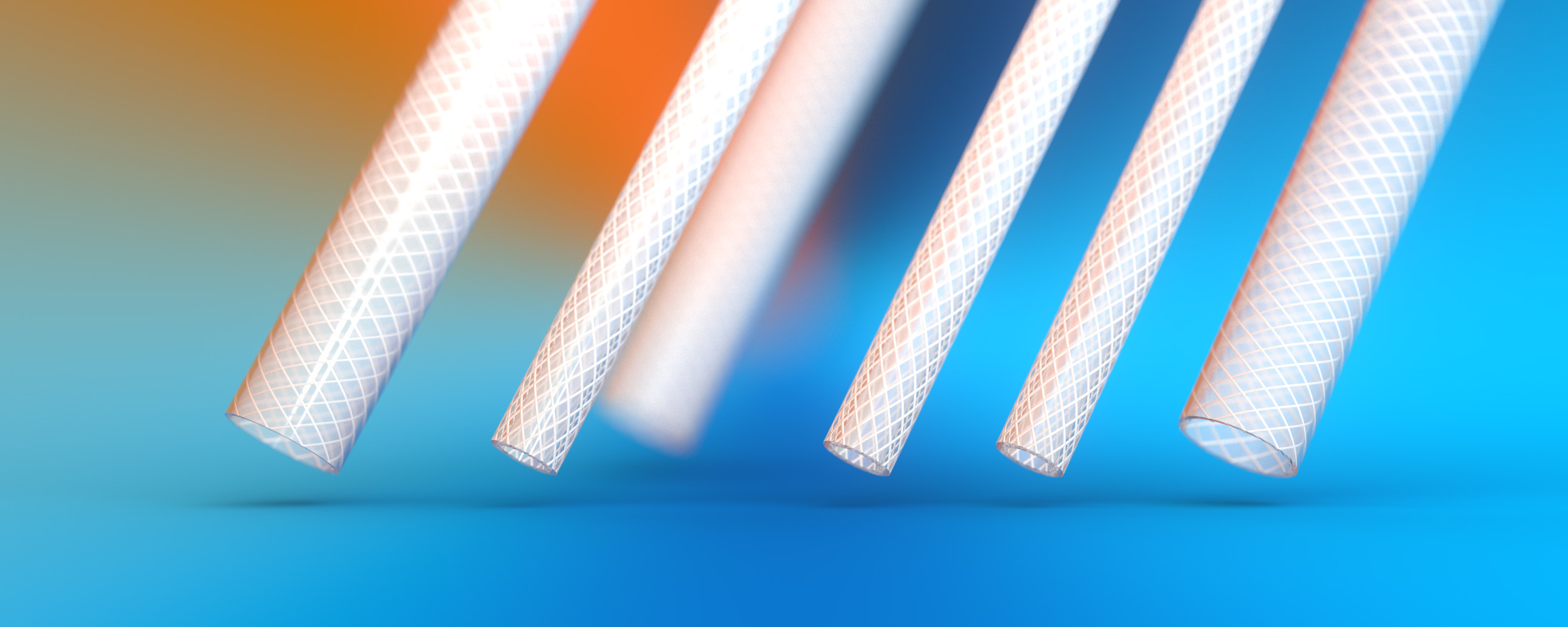

Custom Coil- and Braid-Reinforced Shafts

Our custom coil- and braid-reinforced shafts are designed and manufactured to your specifications. We offer a wide range of dimensions and materials, including polyimide. Contact us to discuss your design intent and we'll work with you to design a complex reinforced shaft with the performance characteristics you need.

Vertical Integration

Our Catheter Center of Excellence helps speed time to market. As the foundation of your catheter-based device, the shaft is critical to catheter performance and function. We offer everything you need to build on that foundation, from leading-edge components to design and development support to high-volume manufacturing. That's how we offer customers the most cost-effective, innovative, catheter-based devices on the market.